PRODUCT

Material: 2205 stainless steel

Finish: Plain

Standard: DIN933

Certification: ISO9001

MOQ:1000PCS

Samples: Free

Place of Origin: Zhejiang China

Product Details

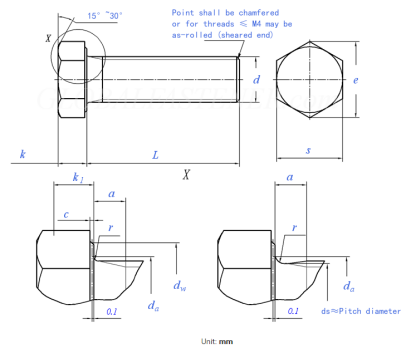

• Item: Full-thread hexagon head bolt + matching hex nut set

• Standard: DIN 933 (ISO 4017) for bolt, DIN 934 (ISO 4032) for nut

• Construction: Single continuous thread from tip to collar, six-sided head for wrench access

| Name | Duplex stainless steel corrosion resistance hexagon bolt |

| Place of Origin | Jiaxing, Zhengjiang, China |

| Size | M5-M100, or non-standard as request&design |

| Finish | plain, zinc plated, black oxide, hot dip galv.et |

| Head Type | hex head |

| Material | stainless steel |

| Standard | DIN933 |

| Non-standards | OEM is available, according to drawing or samples |

| Samples | Samples are free. |

| Package | Bulk in master cartons, then on pallets, or according to customers' requirement. |

| Payment | T/T or L/C |

| SS2205 Chemical Composition(%) | |||||||||

| Grade | C≤ | Mn≤ | P≤ | S≤ | Si≤ | Ni | Cr | Mo | N |

| 0.030 | 2.0 | 0.03 | 0.02 | 1.0 | 4.5-6.5 | 21-23 | 2.5-3.5 | 0.08-0.2 | |

| 2205 Mechanical property | |||

| σb≥ | σb≥ | δ≥ | HB[N(kgf/mm2)] |

| 795(Mpa) | 550(Mpa) | 15% | ≤310(HB) |

| DIN933 | |||||

| Screw Thread d | Pitch P | k | s | ||

| max | min | max | min | ||

| M5 | 0.8 | 3.74 | 3.26 | 8 | 7.64 |

| M6 | 1 | 4.42 | 3.76 | 10 | 9.64 |

| M7 | 1 | 5.04 | 4.56 | 11 | 10.57 |

| M8 | 1.25 | 5.54 | 5.06 | 13 | 12.57 |

| M10 | 1.5 | 6.69 | 6.11 | 17 | 16.57 |

| M12 | 1.75 | 7.79 | 7.21 | 19 | 18.48 |

| M14 | 2 | 9.09 | 8.51 | 22 | 21.16 |

| M16 | 2 | 10.29 | 7.91 | 24 | 23.16 |

| M18 | 2.5 | 11.85 | 11.15 | 27 | 26.15 |

| M20 | 2.5 | 12.85 | 12.15 | 30 | 29.16 |

| M22 | 2.5 | 14.35 | 13.65 | 32 | 31 |

| M24 | 3 | 15.35 | 14.65 | 36 | 35 |

| M27 | 3 | 16.65 | 17.35 | 41 | 40 |

| M30 | 3.5 | 19.12 | 18.28 | 46 | 45 |

| M33 | 3.5 | 21.42 | 20.58 | 50 | 49 |

| M36 | 4 | 22.92 | 22.08 | 55 | 53.8 |

• A2-70 (AISI 304) – 18 % Cr / 8 % Ni, general-purpose corrosion resistance

• A4-70 / A4-80 (AISI 316 / 316L) – 2–3 % Mo added for superior chloride resistance

• Duplex 2205 or 904L available on request for extreme environments

• Tensile strength: 700 MPa (A2-70) – 800 MPa (A4-80)

• Proof load: ≥ 450 MPa (A2-70 bolt) / ≥ 450 MPa (A2-70 nut)

• Temperature range: –196 °C to +800 °C (304) / +870 °C (316)

• Non-magnetic austenitic structure; slight magnetism possible after cold forming

• Self-colour, pickled & passivated per ASTM A967 – bright, contamination-free surface

• Optional mirror polish (Ra ≤ 0.4 µm) or electropolish for food/pharma hygiene

• Salt-spray ≥ 1,000 h without red rust (ASTM B117)